Aerospace

Non Destructive Testing

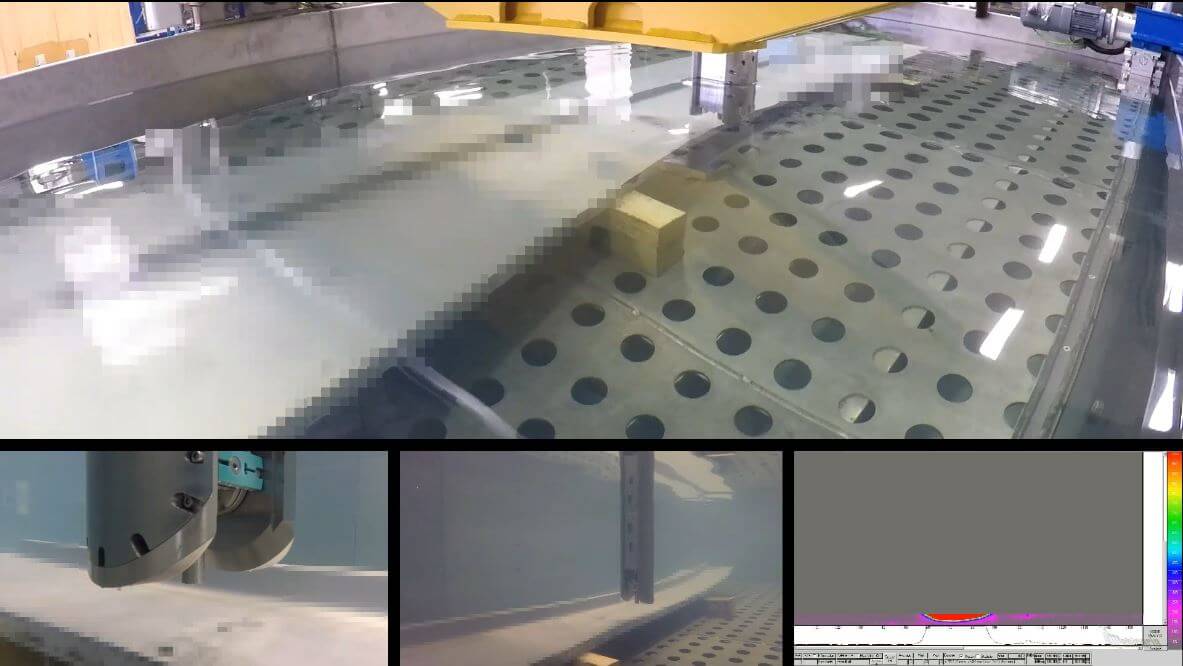

Ultrasonic Scanning Tank

Non-Destructive Testing for Aerospace Structures, Metal Plates and Composites

BIA has been a pioneer in the field of aerospace automated non-destructive testing equipment with its world first fully computerized and automated ultrasonic inspection system for airplane engine introduced in 1987.

Ultrasonic Scanning Tank

Non-Destructive Testing for Aerospace Structures, Metal Plates and Composites

BIA’s tank is used in production process, laboratory and maintenance operation to detect flaws, porosity, foreign objects, delamination, thickness deviation, out-of-plane waviness, in-plane waviness, on avionic structure elements (composites). It can detect flat bottom holes up to 0.2 mm, notches up to 0.10 x 10 mm or FBH at 45° axisymmetric metal plates.

Ultrasonic Scanning Tank

Non-Destructive Testing

for Engine Revolution Parts

Thanks to its high robustness, BIA’s tank is used especially in production process, laboratory and maintenance operation to detect flaws and materiel defects on engine parts (flat bottom holes up to 0.2 mm, notches up to 0.10 x 10 mm or FBH at 45° axisymmetric engine parts).