Engine & Powertrain Testing

Transmission Testing

BIA provides advanced test solutions to evaluate and develop clutch, gearbox, synchronizer or complete transmission.

Durability tests (gear, bearing, differential, casing,…), Noise Vibration and Harshness analysis (NVH), efficiency and quality of gear change are some examples of tests that can be performed.

HEV Test Laboratory

New technologies in EVs and HEVs require new R&D approaches and testing as well as the development of the appropriate tools.

BIA now offers a wide selection of equipement to develop a complete test lab to support the development and testing of electric and hybrid vehicles.

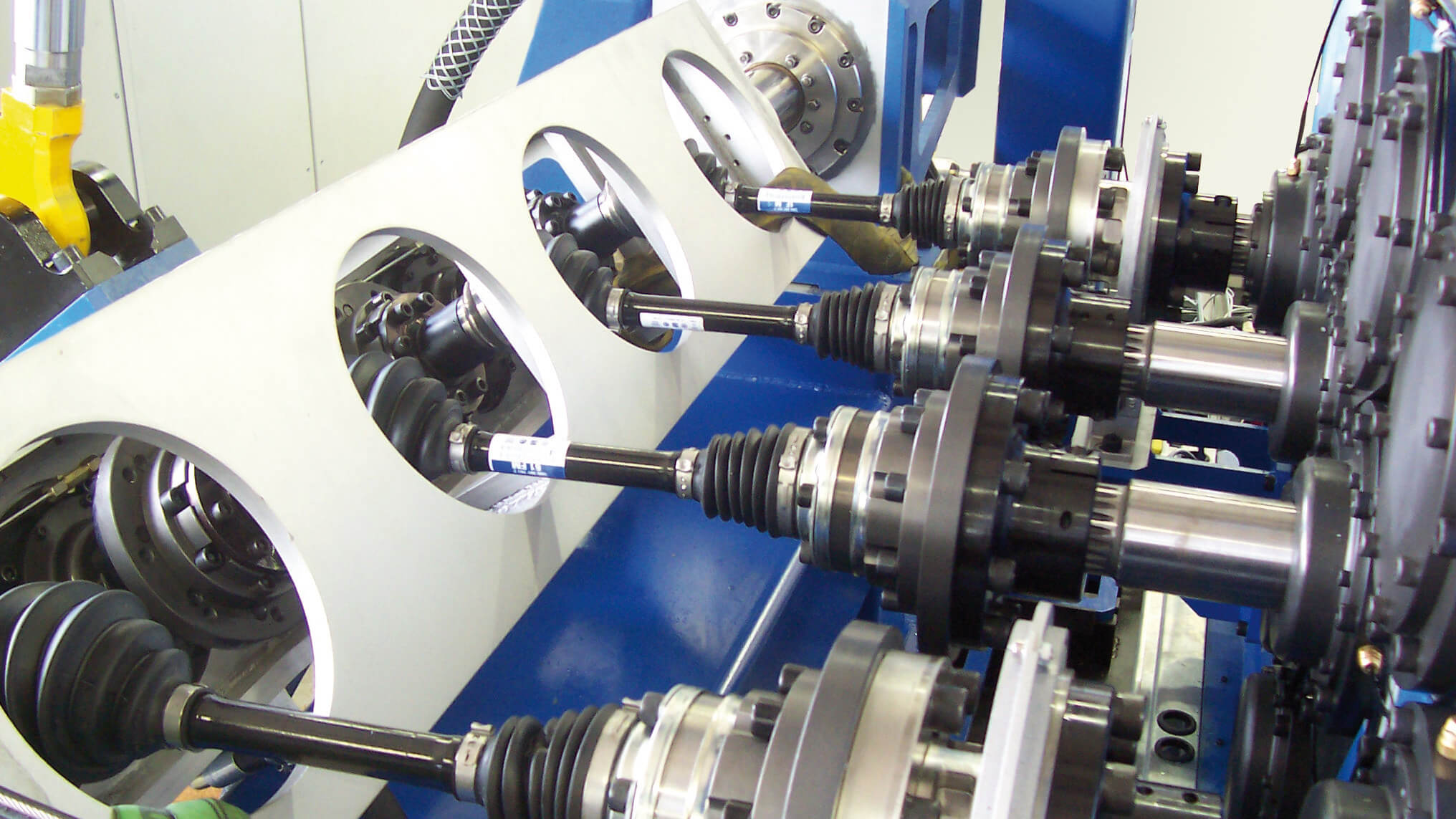

CV Joint Testing

This test system aims at testing the durability of four CV joints in a close kinematic loop.

The rotation speed is similar to the one in vehicle (± 2 500 rpm). A torque up to 4 000 N.m is also applied to this kinematic loop.

E-Motor Testing

Thanks to a unique hydraulic bearing technology, E-Motor and accessories can be tested with exclusive long life dynamometers fully integrated within dedicated test bench.

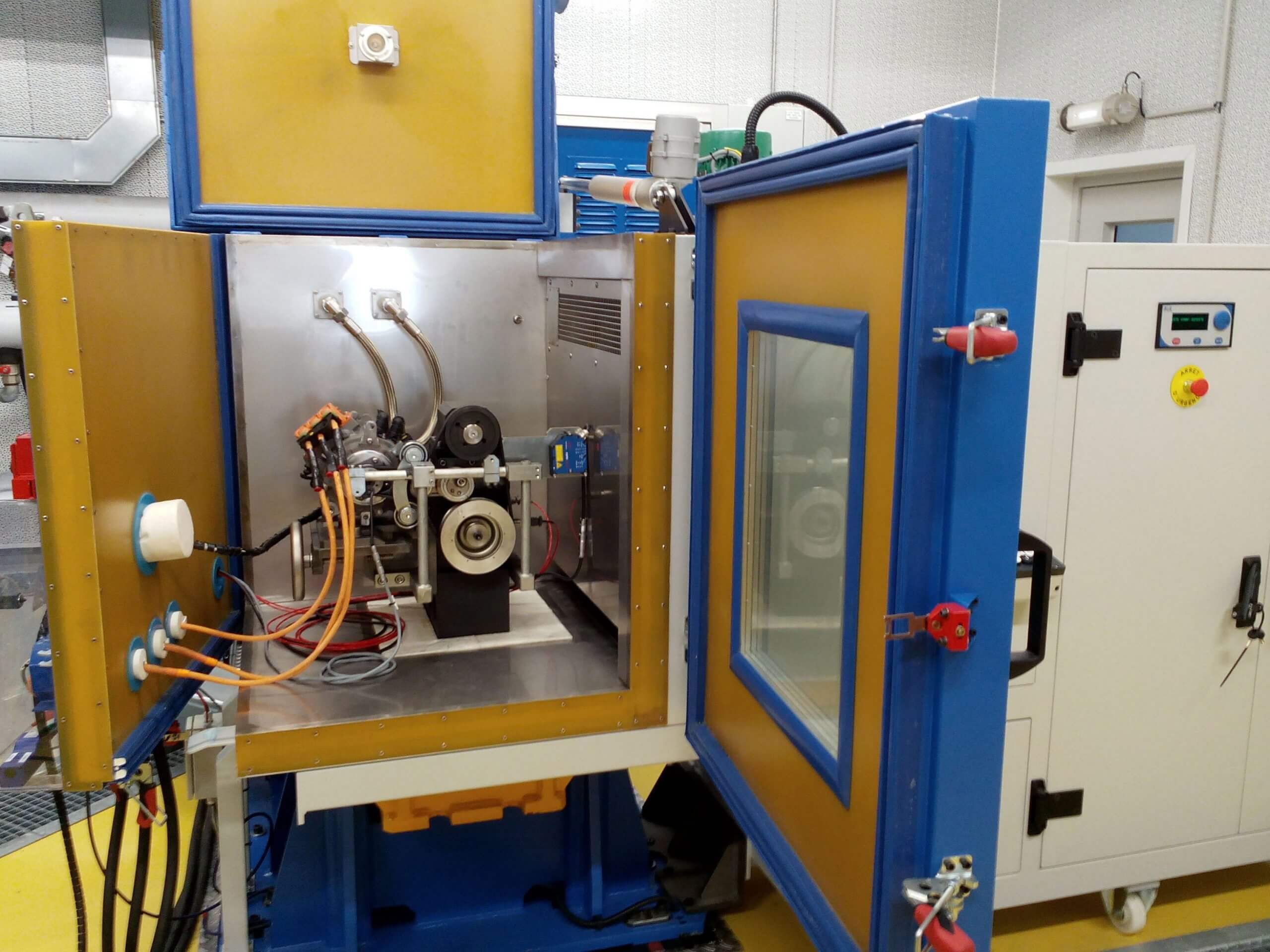

Synchronizer Testing

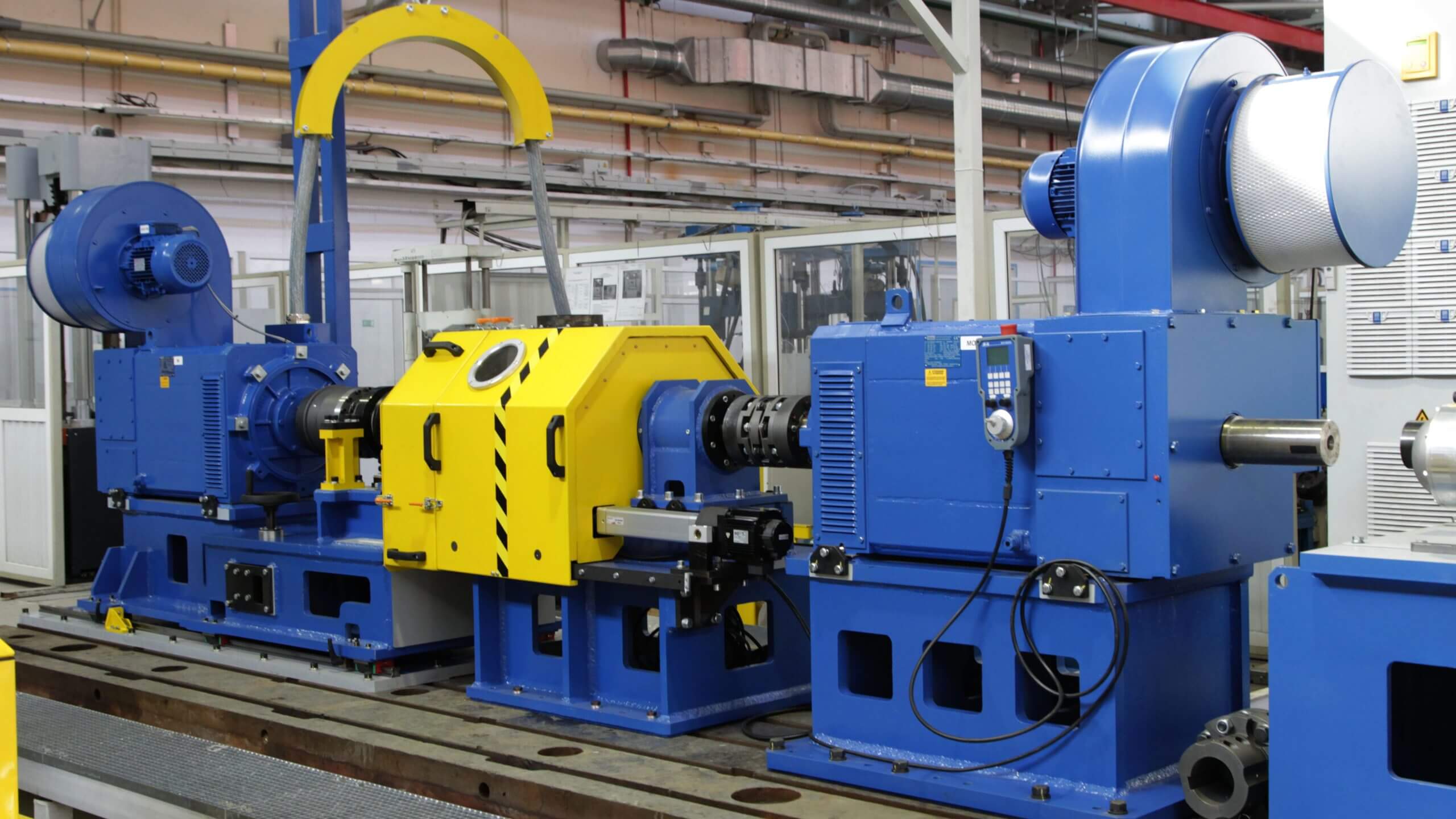

Heavy-Duty Vehicles

The combined clutch and synchronizer test bench designed for heavy-duty vehicles can simulate speed signals from different parts of the driveline, for example from an engine, a clutch, a gearbox, wheels or a chassis.

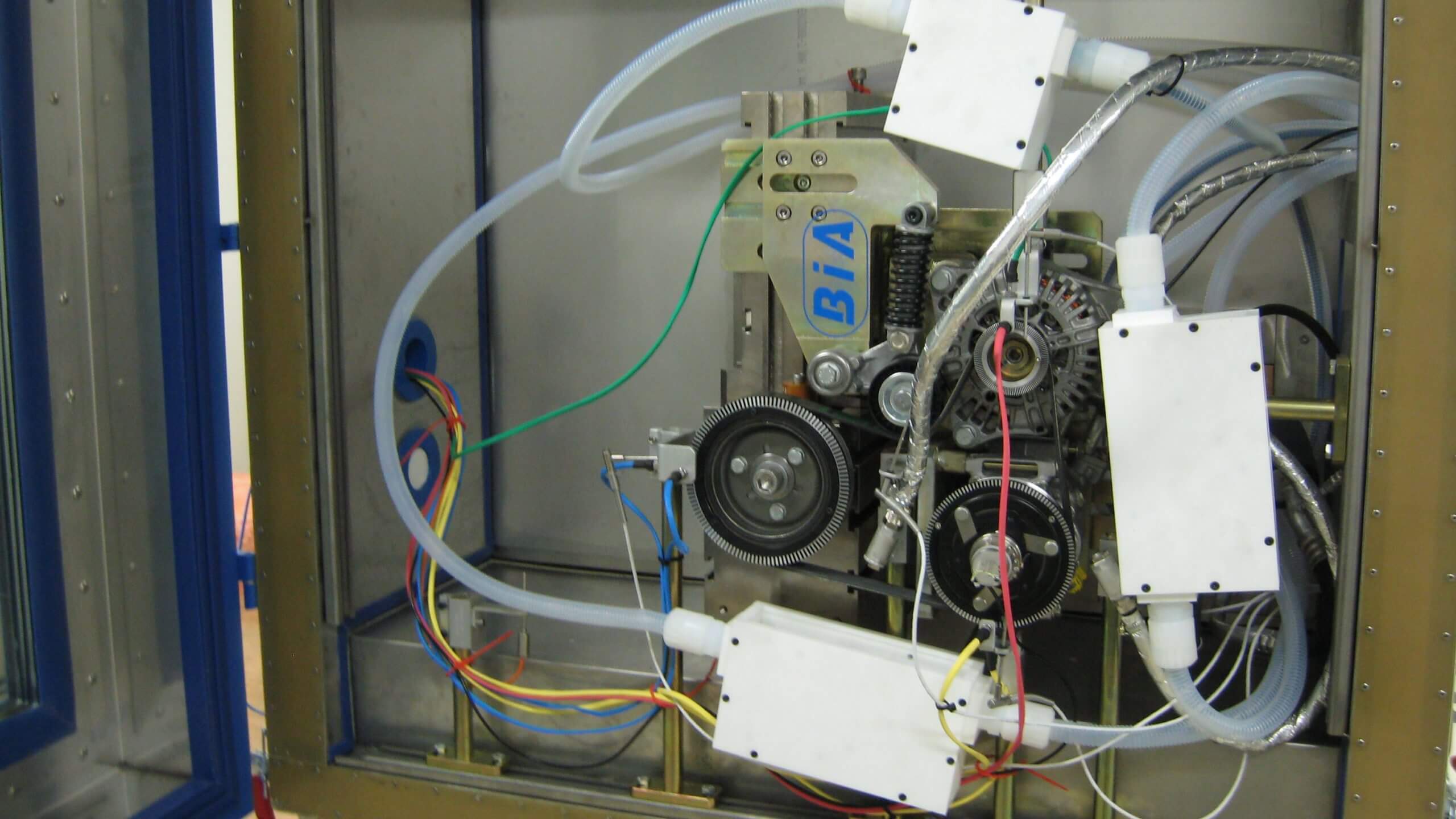

Realistic Engine Simulator

This test system is an innovative solution to simulate different configurations of the engine driven components such as steering pump, alternator, A/C compressor, crankshaft pulley and rollers.